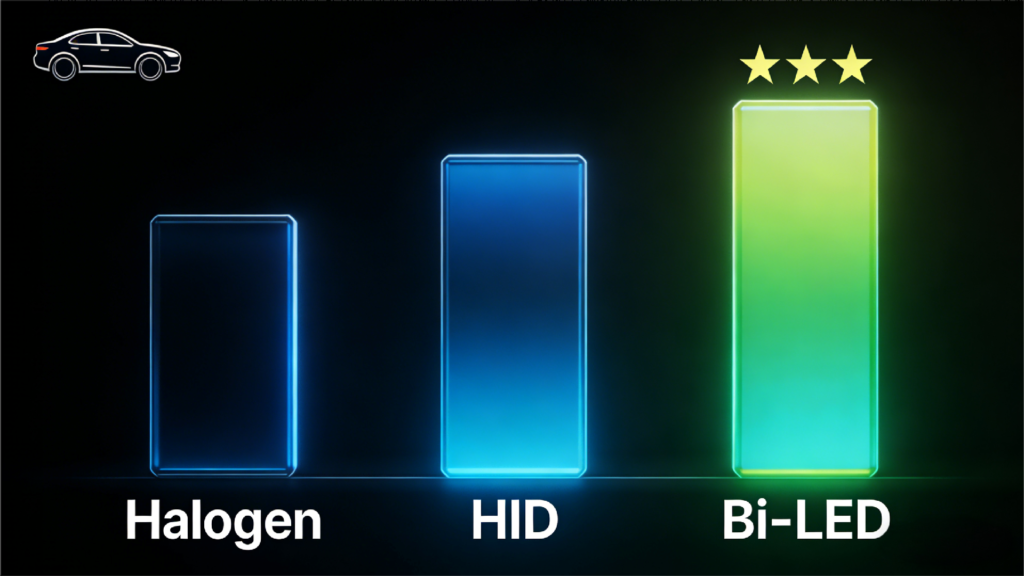

If you have spent any time in automotive enthusiast circles or scrolled through retrofit discussions on Reddit, you know the debate is heated. For years, the gold standard for nighttime visibility was High-Intensity Discharge (HID or Xenon). However, the landscape has shifted dramatically. The bi led projector has emerged not just as an alternative, but as the superior successor in the world of automotive lighting.

This article is not just a definition of terms; it is a strategic comparison designed to help you make an informed purchasing decision. We will dismantle the marketing fluff and look at the raw data: thermal efficiency, lumen density, installation complexity, and long-term reliability. Whether you are upgrading a fleet or your personal vehicle, understanding why the industry is pivoting to bi led projector headlights is crucial.

Module 1: The Technological Shift – How They Work

To compare these technologies fairly, we must understand the fundamental difference in how they generate photons.

The Old Guard: Halogen & HID

Halogen bulbs rely on a resistive filament heating up until it glows. It is inefficient, creating more heat than light. HID (Xenon) systems improved this by creating an arc of light between two electrodes inside a gas-filled tube. While bright, HIDs are complex systems requiring external ballasts to ramp up voltage to ignite the gas.

The New Standard: Bi LED

A bi led system is solid-state technology. “Bi” indicates that a single module handles both low and high beam patterns, usually via a mechanical solenoid shutter. Unlike HIDs, there is no gas to ignite and no filament to burn. Light is generated by the movement of electrons through a semiconductor material. This fundamental difference leads to the primary advantage of LEDs: Instant-On capability. There is no “warm-up” period; you get 100% brightness in milliseconds.

Module 3: The Head-to-Head Comparison (Selection Factors)

When selecting a bi led projector brand, you are essentially balancing three variables: Output (Brightness), Reliability (Heat Management), and Ease of Installation. Let us compare the bi led architecture against its predecessors.

1. Luminosity and Beam Width

While a 55W HID kit can be incredibly bright, it often suffers from a degradation of output over time (known as lumen depreciation). A high-quality bi led projector maintains its output stability much longer.

More importantly, the distribution of light differs. HIDs often have a very intense “hotspot” in the center but may fade at the edges. A premium bi led unit from GTR is engineered to provide a wider beam pattern. This illuminates the sides of the road—crucial for spotting deer or pedestrians—without sacrificing distance visibility.

2. Energy Efficiency and Heat

This is where the bi led shines—literally and figuratively. HIDs run hot and emit high levels of UV radiation, which can eventually burn the reflective chrome bowl inside the projector, causing the headlight to dim permanently over years.

LEDs emit heat backwards, away from the lens. This requires good thermal management (fans or heat sinks), but it saves the delicate optical components from heat stress. This efficiency is why bi led projector headlights are becoming the standard for electric vehicles (EVs) where power conservation is key.

3. Comparison Table: At a Glance

| Specification | Halogen | HID (Xenon) | Bi LED Projector |

|---|---|---|---|

| Startup Time | Instant | 3-10 Seconds | Instant (Milliseconds) |

| Lifespan | 500 – 1,000 Hours | 2,000 – 3,000 Hours | 30,000 – 50,000+ Hours |

| Complexity | Simple | High (Bulb + Ballast + Igniter) | Medium (All-in-one Driver) |

| Lumen Maintenance | Drops quickly | Slow fade over time | Consistent until end of life |

| Color Temperature | ~3200K (Yellow) | 4300K-6000K | 5500K-6000K (Pure White) |

Module 2: Application Deep Dive – The Retrofit Scenario

Why are so many drivers ripping out their old lights for bi led units? The primary application scenario is the “Headlight Retrofit.”

Consider a driver with a 2015 SUV equipped with halogen reflectors. At night, the light is scattered, and in rain, visibility is near zero. The driver considers an LED bulb swap (plug-and-play). However, putting an LED bulb into a halogen housing often results in glare that blinds oncoming traffic because the light source is not in the focal point.

The solution is the bi led projector retrofit. By opening the headlight and installing a dedicated projector module, the driver achieves a perfect “step cutoff” line. This keeps light on the road and out of the eyes of other drivers. This application is particularly critical for lifted trucks and commercial vehicles, where the headlight height naturally risks blinding smaller cars. The bi led cutoff ensures safety and compliance.

Module 6: The GTR Advantage in the Marketplace

In the crowded market of lighting components, GTR has positioned itself as a leader by focusing on material science and optical precision. When comparing a generic bi led projector brand to a GTR unit, two distinct advantages emerge:

- Optical Clarity: GTR utilizes high-grade borosilicate glass lenses. Cheap projectors use lower-grade glass or even plastic, which can cloud over time. Our clear lenses ensure a sharp, colorful cutoff line that enthusiasts desire.

- Thermal Dissipation: As mentioned, heat kills LEDs. GTR employs advanced active cooling solutions with high-speed, quiet fans and copper substrates. This ensures that the bi led chip operates within its safe thermal zone, preventing “thermal throttling” (where the light dims automatically to save itself from burning out).

Module 4: Installation & Maintenance Comparison

For the DIY mechanic or professional shop, the “install-ability” of a product is a major factor.

HID Installation: Requires finding space to mount large ballasts, routing high-voltage wiring harnesses, and often using relay harnesses to draw power directly from the battery.

Bi LED Installation: Much cleaner. Because the driver is often built-in or very small, a bi led projector takes up less space inside the engine bay. There are fewer points of failure—no igniters to fail, no bulbs to shatter. Maintenance is virtually non-existent. Once the housing is sealed, you may never need to open it again for the life of the vehicle.

Module 5: Comparison FAQ

Here are the common questions buyers ask when deciding between these technologies.

Q1: Is a bi led projector harder to install than an HID projector?

Generally, no. It is actually easier. Since the bulb and cooling system are integrated into one unit, you do not have to worry about seating a bulb correctly or dealing with external high-voltage cables.

Q2: Will the bi led fan noise be audible?

In high-quality units like those from GTR, the fan noise is imperceptible from inside the cabin with the engine running. The fans are designed for durability and quiet operation.

Q3: Can I replace just the chip if it fails?

Unlike HIDs where you can replace just the bulb, a bi led unit is a sealed module. If it fails, the whole projector typically needs replacing. However, given the 50,000-hour lifespan, failure is extremely rare compared to bulbs.

Q4: Why is the “cutoff line” so sharp on bi led projector headlights?

The small size of the LED emitter allows for extreme precision. The internal shield can be positioned closer to the light source than in HID systems, creating a razor-sharp transition between light and dark.

Q5: Is it legal to upgrade to bi led?

Regulations vary by country and state. Generally, as long as the light is properly aimed and does not cause glare (which projectors prevent), they are often accepted for off-road or auxiliary use, and increasingly for street use if they meet beam pattern standards.

Conclusion: Making the Right Choice

The era of the halogen bulb is over, and the reign of HID is coming to a close. The bi led projector offers a compelling combination of durability, instant performance, and energy efficiency that older technologies simply cannot match.

If you prioritize a “set it and forget it” solution that provides OEM-level performance (or better), the bi led route is the clear winner. For those seeking the highest quality components for their build, exploring the options at GTR will ensure you are getting technology that is built to last, not just built to sell.